A Control Chart Used To Monitor The Fraction Of Defectives Generated By A Process Is The: . It is a graphical representation of the collected information/data. (or a standard value is given), then the center line and control limits of the fraction nonconforming control chart is $$ \begin{eqnarray} ucl & = & p + 3\sqrt{\frac{p(1.

P-Chart - Wikipedia from en.wikipedia.org

Use c charts for processes in which the measurement system is only capable of counting the number of defects in a sampled unit. If d is the number of defectives in a sample, then the fraction defective in the sample. If a point on a control chart falls outside one of the control limits, this suggests that the process output is nonrandom and should be investigated.

P-Chart - Wikipedia Operations management affinity diagram check list control chart flow chart relationship diagram 10. Similar to a run chart, it includes statistically generated upper and lower control limits. A control chart used to monitor the fraction of defectives generated by a process is the: A control chart used to monitor the fraction of defectives generated by a process is the:

Source: www.winspc.com Number of defects per unit. In this case, you would want to use a p chart. 61 a control chart used to monitor the number of defects per unit is the a p from om 3010 at california state university, stanislaus Leave a reply cancel reply. A control chart used to monitor the fraction of defectives generated by a process.

Source: www.chegg.com The c chart is an industry standard for monitoring and controlling process outputs over time. Leave a reply cancel reply. P chart is also known as the control chart for proportions. 4) 5) the central limit theorem provides. A control chart used to monitor the process mean is the:

Source: www.chegg.com It shows whether the process is in a stable state(in statistical control) or out of statistical control. Control charts 08/02/1439 4 7 the control chart is a means of visualizing the variations that occur in the process data and its components. P = d/n = number of defective unit in a sample/total number of unit or items in a sample.

Source: www.spcforexcel.com C chart is also known as the control chart for defects (counting of the number of defects). A control chart used to monitor the process mean is the: And helps to monitor the process centering or process behavior against the specified/set control limits. A control chart used to monitor the fraction of. Your email address will not be published.

Source: www.isixsigma.com Your email address will not be published. A control chart used to monitor the fraction of defectives generated by a process is the: 3) if all of the control points on a control chart lie between the ucl and the lcl, the process is always in control. If d is the number of defectives in a sample, then the fraction.

Source: towardsdatascience.com 3) if all of the control points on a control chart lie between the ucl and the lcl, the process is always in control. A control chart used to monitor the fraction of defectives generated by a process is the: It shows whether the process is in a stable state(in statistical control) or out of statistical control. It uses binomial.

Source: sixsigmastudyguide.com Number of defects per unit the. The number of defects per unit e. The binomial distribution model for number of defectives in a sample $$ p(d=x) = \left. P = d/n = number of defective unit in a sample/total number of unit or items in a sample A tool used to organize data into logical categories is called a (n).

Source: towardsdatascience.com Operations management affinity diagram check list control chart flow chart relationship diagram 10. Process or product monitoring and control 6.3. (or a standard value is given), then the center line and control limits of the fraction nonconforming control chart is $$ \begin{eqnarray} ucl & = & p + 3\sqrt{\frac{p(1. A control chart used to monitor the fraction of defectives generated.

Source: en.wikipedia.org The binomial distribution model for number of defectives in a sample $$ p(d=x) = \left. If you have attribute data, you need to determine if you're looking at proportions or counts. Control charts are used to determine whether your process is operating in statistical control. A control chart used to monitor the fraction of defectives generated by a process is.

Source: en.wikipedia.org 4) 5) the central limit theorem provides. A control chart used to monitor the fraction of defectives generated by a process is the: Process or product monitoring and control 6.3. It uses binomial distributio n to measure the proportion of defectives or non confirming units in a sample. Aggregate planning is capacity planning for:

Source: blog.kainexus.com A tool used to organize data into logical categories is called a (n) ___. Number of defects per unit the. It shows whether the process is in a stable state(in statistical control) or out of statistical control. 61 a control chart used to monitor the number of defects per unit is the a p from om 3010 at california state.

Source: www.spcforexcel.com A control chart used to monitor the process mean is the: Control charts are used to determine whether your process is operating in statistical control. Number of defects per unit. A control chart used to monitor the fraction of defectives generated by a process is the: A control chart used to monitor the fraction of defectives generated by a process.

Source: bookdown.org A control chart used to monitor the fraction of defectives generated by a process is the: Ch 10 a control chart used to monitor the fraction of defectives generated by a process is the:. Leave a reply cancel reply. Operations management affinity diagram check list control chart flow chart relationship diagram 10. P = d/n = number of defective unit.

Source: www.winspc.com A p chart is used to monitor the fraction of defectives in the output of a from opre 3310 at university of texas, dallas A control chart used to monitor the fraction of defectives generated by a process is the: C chart is also known as the control chart for defects (counting of the number of defects). Control chart is.

Source: www.sciencedirect.com A control chart used to monitor the fraction of defectives generated by a process is the: Let samples of size n be taken randomly from the production process or output at different time intervals. If d is the number of defectives in a sample, then the fraction defective in the sample. A control chart used to monitor the fraction of.

Source: www.isixsigma.com P chart is also known as the control chart for proportions. A control chart used to monitor the fraction of defectives generated by a process is the: A p chart is used to monitor the fraction of defectives in the output of a from opre 3310 at university of texas, dallas A control chart used to monitor the fraction of.

Source: www.chegg.com 3) if all of the control points on a control chart lie between the ucl and the lcl, the process is always in control. Ch 10 a control chart used to monitor the fraction of defectives generated by a process is the:. A control chart used to monitor the process mean is the: If d is the number of defectives.

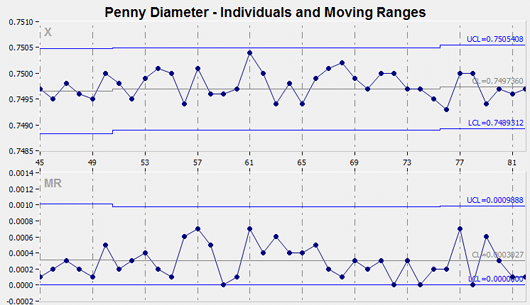

Source: www.spcforexcel.com If a point on a control chart falls outside one of the control limits, this suggests that the process output is nonrandom and should be investigated. Control chart a control chart shows how a process varies over time while identifying special causes of variation and changes in performance. Similar to a run chart, it includes statistically generated upper and lower.

Source: www.itl.nist.gov In this case, you would want to use a p chart. Operations management affinity diagram check list control chart flow chart relationship diagram 10. 61 a control chart used to monitor the number of defects per unit is the a p from om 3010 at california state university, stanislaus The c chart is an industry standard for monitoring and controlling.

Source: www.spcforexcel.com Process variability which statement is an accurate description of a process that is capable? A control chart used to monitor the process mean is the: Control chart is also known as spc chart or shewhart chart. C chart is also known as the control chart for defects (counting of the number of defects). P chart is also known as the.